Textiles cover a range of fabrics and woven goods from natural to man-made items. Apparel, leather good, linens, and other fabrics fit into the category of textiles. These items have another thing in common. They are all things that can be laser engraved. Yes, you can use a laser engraving system to personalize, decorate, and otherwise design things like t-shirts aprons, ties, pillows, curtains, mobile phone covers, tablet covers, laptop covers, purses, luggage, and more.

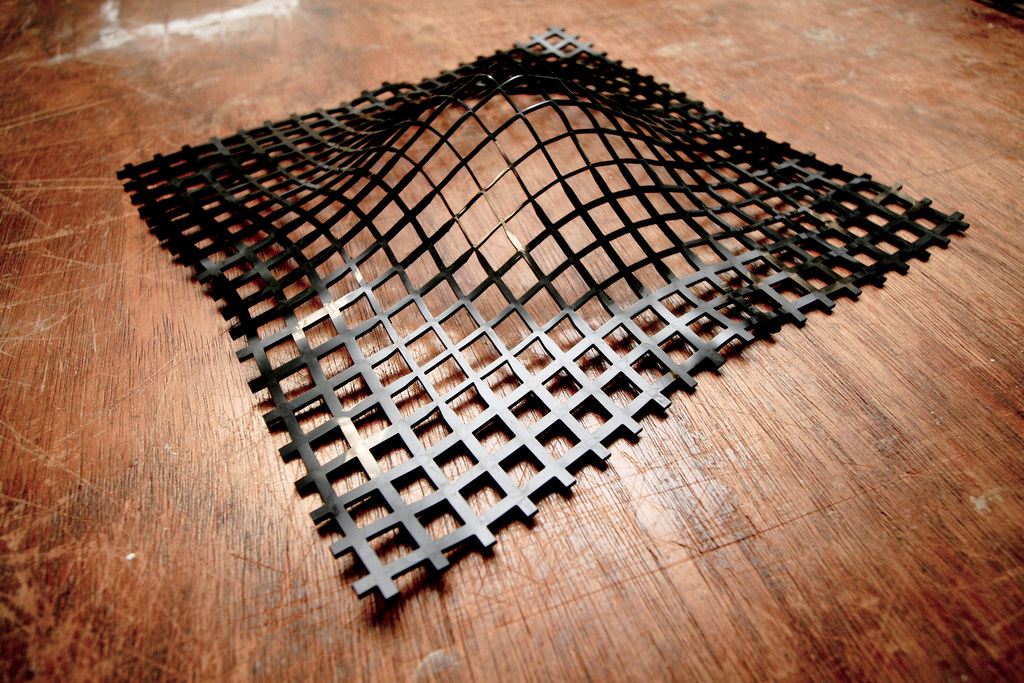

The end result of engraving on fabrics is a high-quality finish that provides a tactile effect. The design possibilities are endless and only limited by your creative spirit. Another nice “side effect” of laser engraving textiles is that the laser beam technology used in this process fuses the edges on materials like polyester and prevents fraying, resulting in an almost perfect finished product.

Textiles that are compatible with laser engraving include:

- Polyester

- Cotton

- Silk

- Felt

- Lace

- Linen

- Softshell

- Fleece

- Neoprene

- Jeans

- Alcantara

Not only is this industry far-reaching for types of materials, but also types of products made from these materials. Laser engraving machines melt the material as it cuts, which is how you get those perfectly finished edges.

The Applications for creating laser engraved textiles include:

- Decorations

- Draperies/Curtains

- T-shirts (clothing in general)

- Promotional items

- Automotive industry

- Design

- Arts & Crafts

Single-layered fabrics can be engraved/cut faster and more efficiently with a laser engraver than with a knife or other manual cutting tool. The laser engraving process is a tool-free, non-contact process. Textiles/fabrics aren’t touched in the process. That means the fabric won’t get warped. Instead, you get a final product that is clean, neat, and beautifully finished. Usually, there are no seams required with this process.

Accurate cutting is one of the reasons laser engraved textiles come out so perfect. Flags, banners, napkins, and anything with a fine, straight edge require this kind of precision. There is also no need to position or reposition the material because the movement is adjusted automatically via programming. Many of these laser systems have a vision camera feature that allows for perfect contouring.

Laser engraving machines used in textile cutting work with graphics programs just like with any other laser engraving process. Therefore, there is no new learning curve for programming if you decide to expand your laser cutting business to include textiles.

The same benefits you get from a successful laser engraving business apply to the fabric niche. If you’re already in the business, it will only boost your revenue. If you want to niche in this area only, it’s a good way to get started in the business.

You can personalize items for personal gifts like these:

- Barbecue gloves

- Placemats and Napkin sets

- Wall hangings

- Fleece tops or jackets

- Pet beds

- Table runners

- Decorative throws

Every one of these would make a unique gift idea for the person who has everything.

The laser engraving industry is one of the most lucrative and one of the most inexpensive ways to start a business. Laser engraving/cutting machines start at about $7,500 for a good-quality system. It’s a great place to start and you can upgrade as you become more successful.

Article by Needham Coding